Technical Service

Roll is the main consumable of steel rolling. In the rolling process, the consumption of roll mainly has two kinds of phenomena: 1.The gradual wear of roll surface, 2. The consumption caused by various cracking phenomena.

▪ Roll failureIn the process of hot rolling, the service life of the roll will be shortened when there are some factors that restrict the continuous use of the roll. These constraints include: roll cracking, flaking, and roll breakage.

—— roll crackingIt is very difficult to avoid roll crack, but it can be controlled by careful observation. If the roll crack is formed around the roll such as the bottom of the rolling groove, it may cause the roll to break. In this case, there is usually a dark area on the circumference of the cracking surface, sometimes it is crescent shaped, sometimes it extends to all directions of the circumference.

The best way to avoid the radial crack is to separate the roll quickly, which is a process requiring dynamic reduction mechanism. If the roll cannot be separated quickly, for example, when the bar is sandwiched in the roll, the possible way to limit the roll crack to the minimum is to immediately shut down the roll cooling water.

—— flakingThere are many factors that can cause spalling, the most common being fatigue and overload. Fatigue induced spalling usually occurs on rougher rolls, such as those that work long hours under high surface tension. The roller bodies of these rollers are under alternating tensile and compressive stresses. If the fatigue limit of the roller material is exceeded, the spalling will occur under the surface. Therefore, the surface material of roller should have excellent fatigue strength.

—— roll breakageIf this happens to the roll, it is obvious that the cause is the stress caused by the improper position or too cold of the rolling material in the rolling groove, or the improper use of cooling water. Other causes include nicks, deep roll cracks, etc. The broken roll caused by thermal stress usually appears at a certain angle of the roll axis with sharp edge shape.

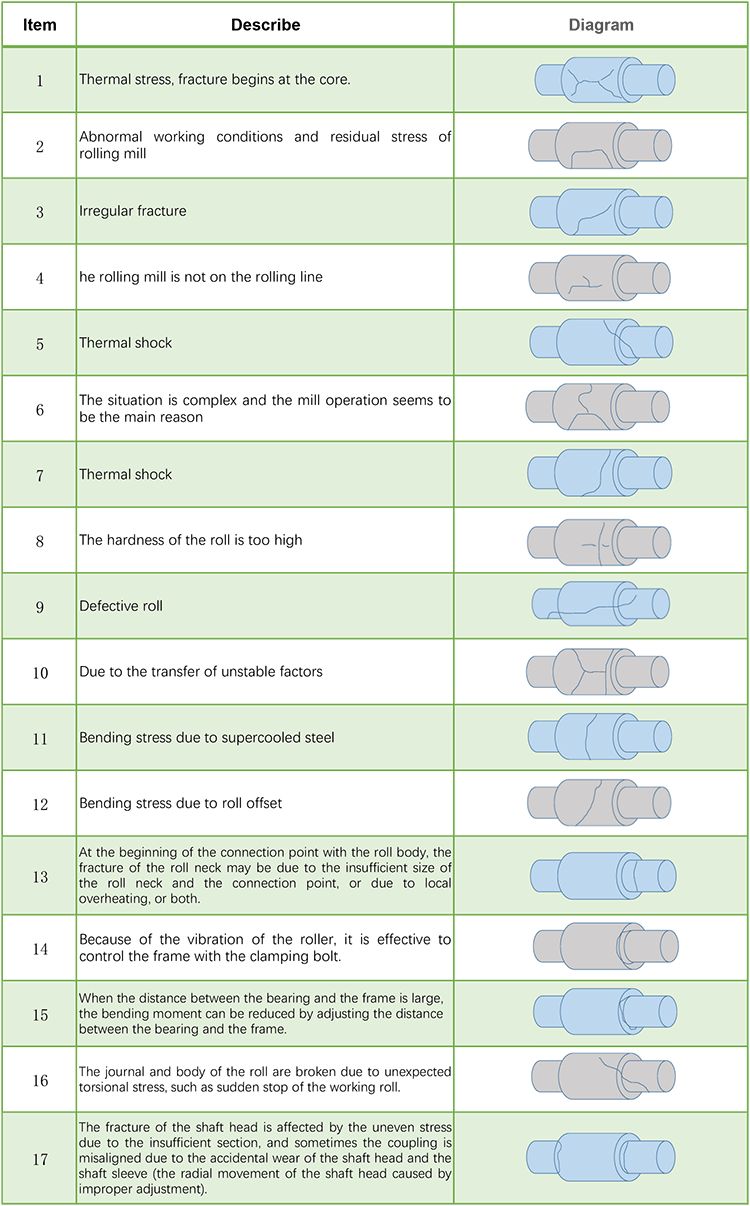

▪ Investigation on the cause of roll fractureThe broken roll can be checked by carefully analyzing the mechanical stress, thermal stress and internal stress when the roll is working. The mechanical stress is caused by the bending, torsion and fatigue of the roll, and the thermal stress is caused by the uneven temperature of the roll. The internal stress is produced during the solidification process from the outer surface to the core after the roll casting.

—— Following are the types of broken rolls: